ELECTRIC TRIKES AND MOUNTAIN BIKES:(Click here for a few pictures of the trikes and bikes in 3D)SCORPION 'INTERCEPTOR' E-TRIKE ASSIST PROJECTMy wife said three things when I told her I wanted to put electric motors on our new HP Velo Scorpion recumbent trikes (obtained as stable comfy more old-age-appropriate ride-replacements for our mountain bikes): 1. Don’t you dare trash my sweet ride. 2. Make it not scary for a non-tech person to operate. 3. Make it pretty. My own goals were a) to easily make the run from town up to my house (~3000 vertical feet in 4.5 miles), b) run efficiently at both low and high speed, and c) look cool. I tested a BMC hub-motor and didn’t like the power band, nor the gear knashing noise, and so chose RC mid-drive. I decided to go for a MadMax Interceptor look, with its big timing-belt turbo spinning up at the flick of a switch. A belt-reduction unit would be user field serviceable, and that seemed a big plus. The main problem with the HP Scorpion is that because of the full suspension and complicated driveline, there is little usable space behind the seat to locate a drive unit, as has been done nicely on a number of other trikes (e.g. like FFR’s) that have squarish or extendable frames. Fortunately Matt S (recumpence) offered to build me a couple of flexible and beautifully-made 2 stage reduction units that I could modify to fit under the front boom. The key idea was simply to rotate the boom extension 180 degrees to put the symmetric (i.e. works the same CW or CCW) Schlumpf high-speed pedal-drive on the left side. This allowed for installation of a double freewheel and jackshaft in a quite tight area (with a net clearance of like 1/8 inch or so), to drive the main chain-line on the right after a couple of low-angle re-directs. Here are some pictures of the build.

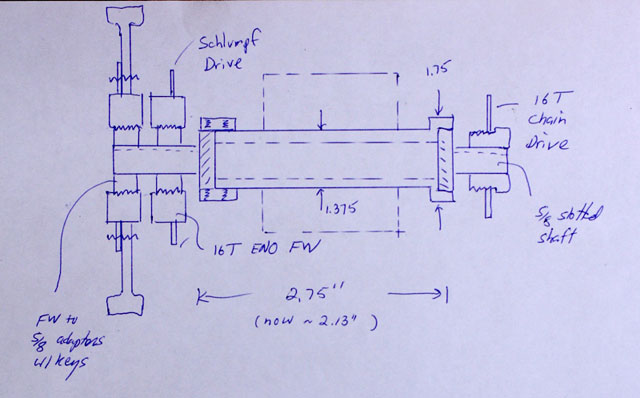

Design Sketch - Front bearing tube with freewheels (FW) The main modification to the two stage davinci drive was to replace the 2nd stage bearing tube with a new one, holding a keyed 5/8 shaft (vs. unkeyed ½”). This allowed two ENO freewheels to be squeezed side by side in the small area between the pedal and the boom, linking to the 8mm drive pulley and the pedal chain.

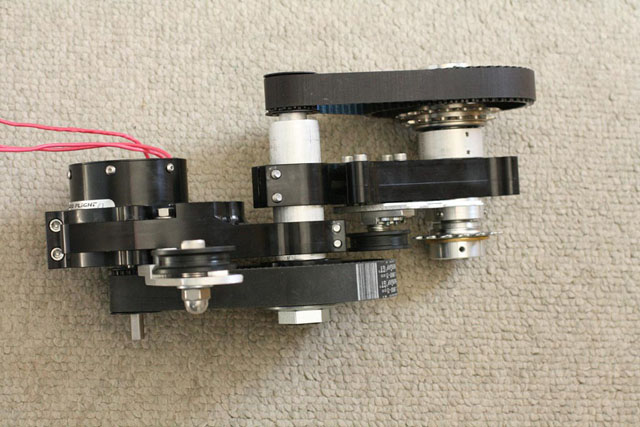

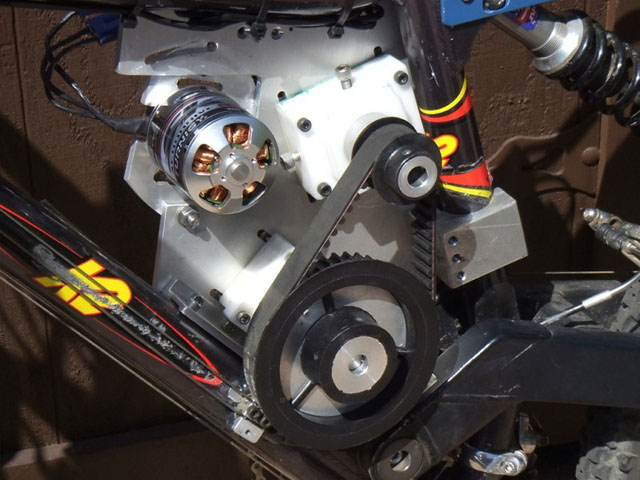

Modified Recumpence davinci 2 stage drive with Astroflight 3215 motor. Black parts by Matt, silver parts and chain rollers are my mods. Total weight with Astro 3215 motor = 11 pounds. My mods (heavy ENO freewheels, bigger shafting, etc.) added ~3 pounds.

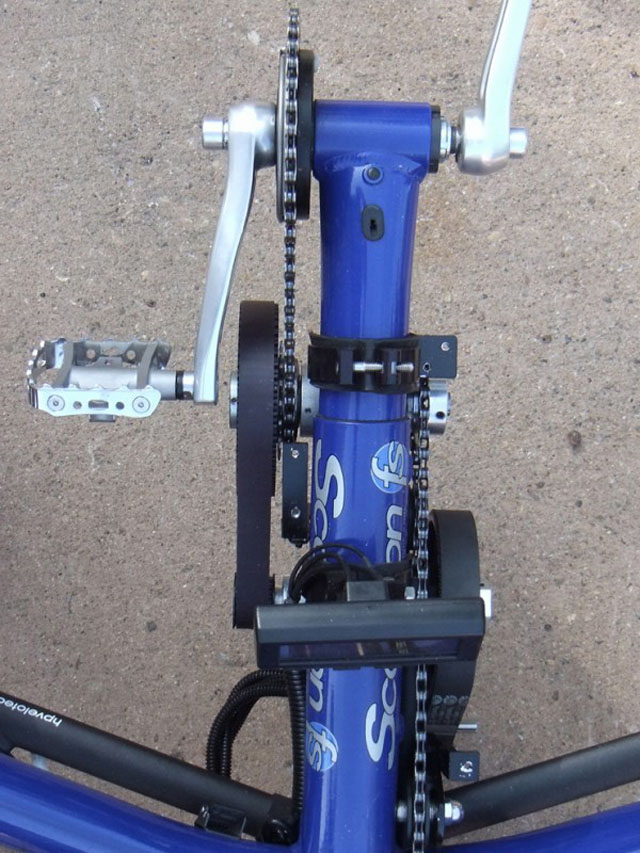

Top View Front Boom My wife and I are short, so everything is tight. But it all runs smooth with no scrapes or bindups, in the first few hundred miles anyway. The motor unit is held by two super-neat recumpence boom clamps, and by extending three large existing frame bolts into custom attachments I put on the reducer body. It ain’t moving nowhere.

Nice thing about the Schlumpf high speed drive is that with motor at full speed, you can still pedal-assist at a reasonable turnover rate (about 90rpm). The kick-shift for starts, etc., is way nice.

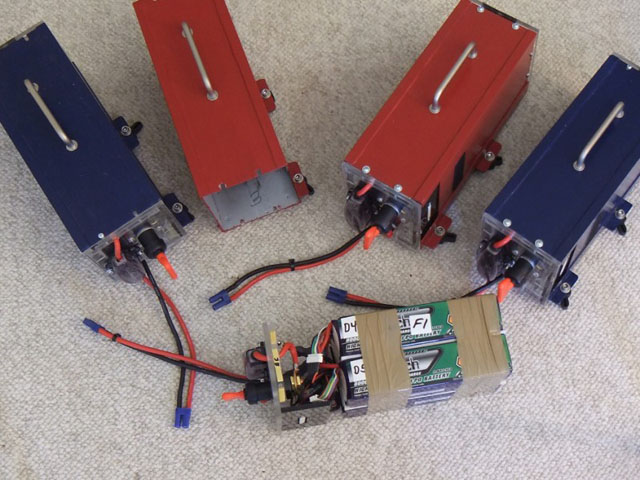

The pulley ratios are 20-80 (5mm pitch x 1”wide), 14-50 (8mm pitch x 7/8”wide), and 16T with 9 speeds (11T – 34T) in the back. After foolishly showing my wife some videos of LiPo’s burning, I calmed her down a bit by installing quick release battery mounts. Though under the seat (well, there was no better place), a quarter turn of two huge wingnuts and a light pull gets the thing off. I sure would hate to burn up these trikes (see her point #1 J).

12S (~48V) 16Ah Lipo batteries Battery installed. DB25 connector is for cell-log and charging cable attachment. Some specs: Fullup weight (with one 13 pound 12S, 16Ah battery) about 73 pounds. Min ground clearance: 4.5”. Top speed (as geared above, on the flats), Astro3215 – 40mph, Astro3220 – 45mph. I’m sure a different gearing would get you over 50, but holy crap, even 40 seems pretty scary to me! It takes about 7Ah to go the 9miles home from downtown (4.5miles on the flats and then 4.5 miles up about 3000 feet). Great fun! Mountain Bike Builds (2D)I had a lot of parts left over from adding mid-drive motors to our two trikes. Timing belt pulleys, bearings, shafts, freewheels, some cheap motors, HV80 controllers, etc. So I decided to go back to our old mountain bikes, which were temporarily abandoned in favor of the more stable and comfortable recumbent trikes, and see what I could do to add 2-stage belt-reduction electric crank-drive assist to them. Worked out surprisingly well, using the cheap parts (like narrow plastic pulleys and Turnigy motors, perhaps $300 total per drive). Hopefully we can attack the slickrock in Moab this fall. Some Pix:

I had built a gas-assisted (30cc 4 stroker) mountain bike in 1997. I used it for canyoneering (hide the bike at the end of a long canyon, do the technical descent, motor-assist back to the car at the head of the canyon after a long day). Deep sandy back-roads in Utah gave it a workout, but it made it (after letting air out of the tires). However, the engine was noisy and riding was quite awkward. So I decided to remove the gas engine, and install a lighter/smaller/quieter electric drive with a timing-belt 2 step (~18:1) plus chain crank (5:1) reduction system.

A 5mm pitch by 15mm wide first stage belt has proved adequate (no skipping at all). Surprise to me: I haven’t been able to break the cheap and lightweight plastic pulley.

Second stage required 8mm pitch to avoid skipping on hard full-power up-shifts.

The big 10S 20Ah lipo battery I originally made for the bike is a bit heavy, high, and far back for anything but mild roads. Kind of kills the maneuverability.

A smaller battery (12S 8Ah) on the cross bar feels better.

My wife’s old mountain bike, similarly converted. This second bike-build has the motor, gearing, and battery lower down and it rides a lot better.

Tiny Turnigy 6374 (max ~2hp) Motor and 8mm pitch 2nd stage belt. 48V 8Ah battery below. Motor was later replaced with a quieter (less whining) Astroflight 3210.

First stage (5mm pitch, 15mm wide HTD belt), HV80, and crank drive.

Top View. Have to be careful with these. Easy to do unanticipated wheelies. Can’t wait to hit the slickrock…….

|

© Hart3D - All Gallery images and videos are copyrighted John Hart. All rights reserved. No part of these pages, either text, videos, or images, may be used for any purpose other than for personal viewing. Reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical, or otherwise, is strictly prohibited without prior written permission.

|